Understanding Rexroth Pumps: Features, Benefits, and Applications

Table of Contents:

In today’s fast-paced industrial world, the demand for reliability, efficiency, and performance in machinery is more pressing than ever. Are you struggling to find dependable solutions for your hydraulic needs?

You’re not alone. The sheer number of options can feel overwhelming, and if you choose wrong, it leads to costly mistakes and inefficient operations. Unfortunately, it’s difficult to find the right components to boost productivity while ensuring cost-effectiveness and longevity.

At Mission Hydraulics, we understand the frustration, and we believe everyone deserves access to reliable, high-performing equipment. Enter Rexroth pumps, a name synonymous with precision engineering and superior performance.

In this blog post, we’ll explore everything you need to know about Rexroth pumps. We will look at their advantages and key applications across various industries and provide guidance on choosing the perfect pump for your needs. With our expertise in the industry, we’re here to provide you with invaluable insights and support throughout your decision-making process

What are Rexroth Pumps?

Rexroth pumps are the hallmark of excellence in hydraulics and automation technology.

They are renowned for their efficiency and reliability. Originating from Bosch Rexroth AG, a globally recognized leader in drive and control technology, these pumps are engineered with precision to cater to diverse industrial applications. With a legacy extending over two centuries, Rexroth has continually evolved, integrating innovation and cutting-edge technology to set industry standards.

The success story of Rexroth began in 1795 when it was founded as an iron foundry in Lohr am Main, Germany. Over the centuries, the company has transformed, tipped by the acquisition by Robert Bosch GmbH in 2001, propelling it onto the global stage. They’ve consistently pushed the boundaries of pump technology, achieving significant milestones in efficiency, durability, and precision. Its continuous commitment to excellence is evident in its wide range of pump models designed for various industrial applications. Today, Rexroth’s commitment to quality and performance remains unchallenged, making its pumps a preferred choice for industries worldwide.

Pros and Cons of Rexroth Pumps

Being well-informed means looking at both the strengths and weaknesses of a product. Rexroth pumps, like any technology, have their advantages and limitations.

Pros:

- Reliability: Renowned for their robust construction, Rexroth pumps deliver consistent performance, reducing the likelihood of downtimes and maintenance needs.

- Efficiency: Known for their high efficiency, Rexroth pumps reduce energy consumption and operational costs.

- Innovation: Bosch Rexroth consistently integrates the latest technology into their products, ensuring modern and efficient solutions.

- Customization: A wide range of models and specifications allows businesses to select pumps tailored to their needs. This customization allows for diverse applications and operating conditions.

- Global Support: With a global presence, customers can rely on a comprehensive support system for troubleshooting or spare parts.

Cons:

- Cost: The resourcefulness and engineering quality of Rexroth pumps come at a premium price, which might be a concern for startups or small businesses. Using aftermarket parts rather than OEM can help mitigate the long-term cost associated with Rexroth pumps.

- Complexity: The state-of-the-art technology incorporated in Rexroth pumps can sometimes mean needing specialized knowledge or training for optimal use and maintenance.

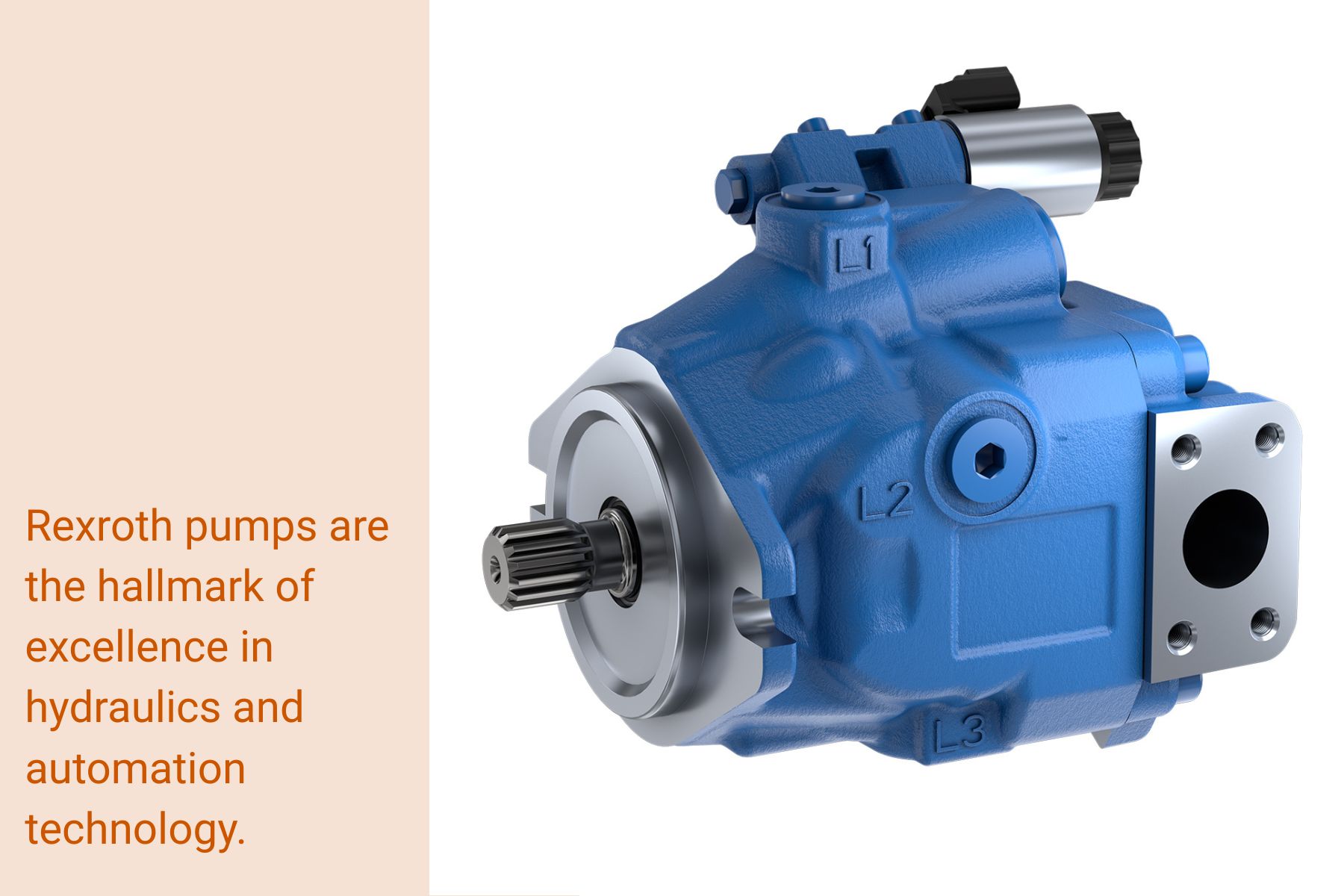

Key Applications: Where Rexroth Pumps are Used

Rexroth pumps find applications across a myriad of industries. Each benefits from the technology in unique ways. Their versatility shines through in demanding environments.

- Manufacturing and Production: Rexroth pumps provide the precise hydraulic pressure needed for different manufacturing processes, from metalworking to assembly lines.

- Construction: Reliable hydraulic systems are critical for cranes, excavators, and other heavy machinery operations in the construction sector, where Rexroth pumps shine.

- Marine and Offshore: The demanding environment of marine and offshore industries necessitates durable solutions, where the seawater-compatible Rexroth pumps come into play.

- Agricultural Equipment: Farmers benefit from Rexroth pumps in their machinery, optimizing productivity and maintenance needs across expansive operations.

- Automotive: Used in car manufacturing processes, Rexroth pumps aid in creating efficient and precise automotive components. They play a vital role in assembly lines and testing equipment.

- Aerospace: Rexroth pumps are used in aerospace applications where reliability and precision are paramount.

These are just a few examples. Rexroth pumps have proven their effectiveness in numerous other sectors. They improve efficiency and streamline operations across various conditions.

Benefits of Rexroth Pumps: Efficiency, Durability, and Performance

The hallmark of Rexroth pumps is their unparalleled blend of efficiency, durability, and performance. The benefits of choosing Rexroth pumps are substantial:

- Efficiency: Designed to maximize energy use, these pumps reduce operational costs, contributing to more sustainable processes.

- Durability: Built to withstand harsh conditions, Rexroth pumps have long service lives. This minimizes disruptions and ensures lower costs associated with replacements and repairs. (Of course, all equipment eventually breaks down, so we offer high-quality aftermarket parts for Rexroth pumps.)

- Performance: High throughput and precision make these pumps ideal for operations requiring uncompromised reliability and quality.

- Innovation: Rexroth continuously innovates, incorporating the latest technology into their pump designs. Recent advancements include improved efficiency through advanced materials and designs. Some newer models incorporate digital tools and IoT (Internet of Things) capabilities for enhanced monitoring and predictive maintenance.

Rexroth is at the forefront of research into next-generation pump technologies. The company constantly seeks to improve efficiency and sustainability. These benefits ensure that Rexroth products continually offer businesses a substantial return on investment.

How to Choose the Right Rexroth Pump for Your Needs

Selecting the right Rexroth pump involves considering several factors to ensure optimal performance. Follow these steps:

- Consider your operating environment: Consider factors like temperature, pressure, and potential contaminants.

- Determine Your Requirements: Analyze the specific needs of your operation to understand the hydraulic capacity required. Calculate the volume of fluid you need to pump per unit of time. Assess the required pressure rating for your application.

- Consult Experts: Seek advice from professionals familiar with Rexroth products to match your application’s needs with the correct model.

- Future Growth: Consider potential future expansions or changes in your operational requirements; flexibility is key.

- Budget: While cost is essential, focus on the total value, including efficiency and maintenance costs, rather than just the purchase price.

- Tech Support: Ensure the provider offers robust support, which is essential for addressing any issues efficiently.

Use this checklist to guide your decision:

☐ Assess operating environment conditions

☐ Determine the required flow rate

☐ Define pressure requirements

☐ Evaluate fluid viscosity

☐ Consider budgetary constraints

Once you've gathered the necessary details using this checklist, you can make an informed decision on the right hydraulic pump for your needs. Start by evaluating the operating environment, as extreme conditions like temperature or exposure to dirt can influence the pump's durability and performance. Next, determine the required flow rate and pressure to ensure the pump can handle your system's demands. Fluid viscosity affects pump efficiency, so ensure compatibility with the fluid you're using. Finally, factor in your budget to narrow the options while keeping quality and performance in mind. Considering these factors, you can select a hydraulic pump that meets your technical needs and financial constraints. Detailed criteria and best practices give further insight into choosing the right pump. If unsure, consulting with a qualified professional (like Mission Hydraulics) is highly recommended.

Conclusion

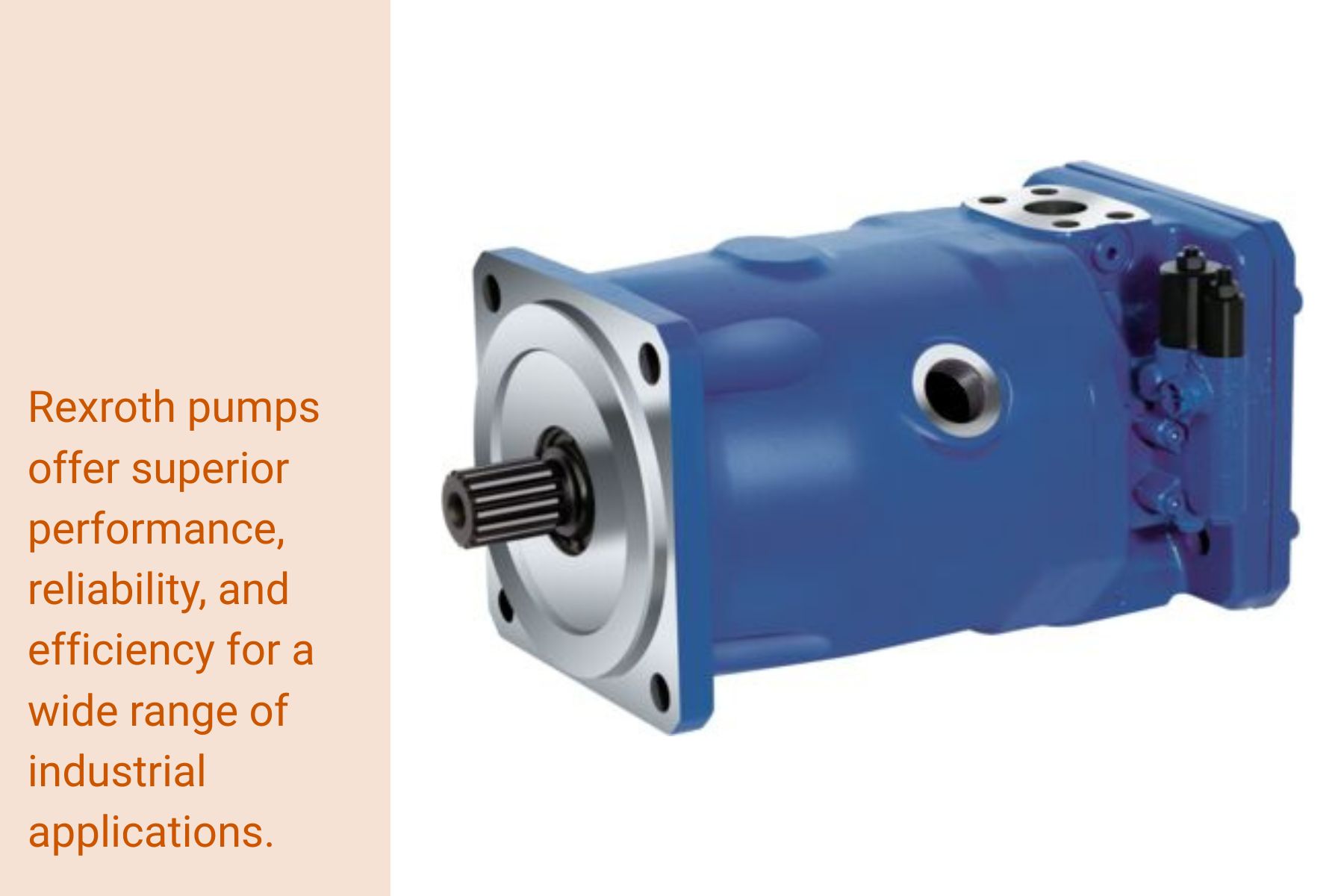

In conclusion, Rexroth pumps offer superior performance, reliability, and efficiency for a wide range of industrial applications.

They undeniably stand out as a reliable and high-performance choice in the world of hydraulic systems. Their robust designs, advanced technologies, and commitment to customer support make them a valuable asset for any operation.

Equipped with this knowledge, you are better prepared to select the right pump that meets your current demands and supports your long-term operational strategies. For expert guidance and a wide array of aftermarket Rexroth products catered to your unique needs, we invite you to explore our offerings and reach out to our team for dedicated support. Your journey to efficient and top-tier hydraulic solutions starts now.

Ready to experience the difference Rexroth pumps can make in your operation? Contact us today for personalized guidance and a quote tailored to your requirements.