Is Your Hydraulic Pump Trying to Tell You Something? Here’s How to Listen

Table of Contents:

Imagine this: you’re in the middle of a crucial production run, and suddenly, your machinery grinds to a halt. The culprit? A failing hydraulic pump. The inconvenience and costly downtime are enough to make any business owner shudder.

At Mission Hydraulics, we understand the frustration and financial burden this can cause. The smooth operation of your machinery largely depends on the state of its hydraulic pumps. But like any vital components, they’re susceptible to wear and tear. Catching early signs of failure can save you from unexpected downtimes and costly replacements.

Hydraulic pumps are complex, but you don’t need to be an expert to notice when something’s off. The good news? You can learn how to identify these issues. You need to operate your machinery without the fear of an impending breakdown. That’s where we come in—we’re here to guide you through the signs and symptoms your hydraulic pump might exhibit when it’s under duress.

This blog post will guide you through recognizing the early warning signs of hydraulic pump failure, allowing you to address problems before they escalate into major crises. Our company boasts decades of experience in the machinery sector, providing expert solutions and services for all your hydraulic needs.

Let’s dive into the journey of understanding your hydraulic pump better.

Common Symptoms of Hydraulic Pump Failure

Hydraulic systems are the workhorses of many industries. They convert mechanical energy into hydraulic energy, which powers various components of heavy machinery. With such an important role, their failure can halt operations. Identifying problems early prevents minor issues from snowballing into catastrophic ones. So, what should you look out for?

- Unusual Sounds: Listen closely. Any whining, knocking, or grinding noises might signal that your pump is having trouble. More specifically, it could indicate air getting into the system or worn-out parts.

- Inconsistent Pressure: Do you feel that the machinery is lacking its usual strength? That could be a clear indicator of a failing pump.

- Excessive Heat: Hydraulic systems shouldn’t run hot. If you notice abnormal heat, it might be time to inspect the entire system.

- Fluid Leaks: Any hydraulic fluid pooling where it shouldn’t could suggest seal degradation. Look for leaks around seals and fittings, as these are clear indications of problems. Discolored hydraulic fluid, such as darkening or becoming cloudy, suggests contamination or internal wear.

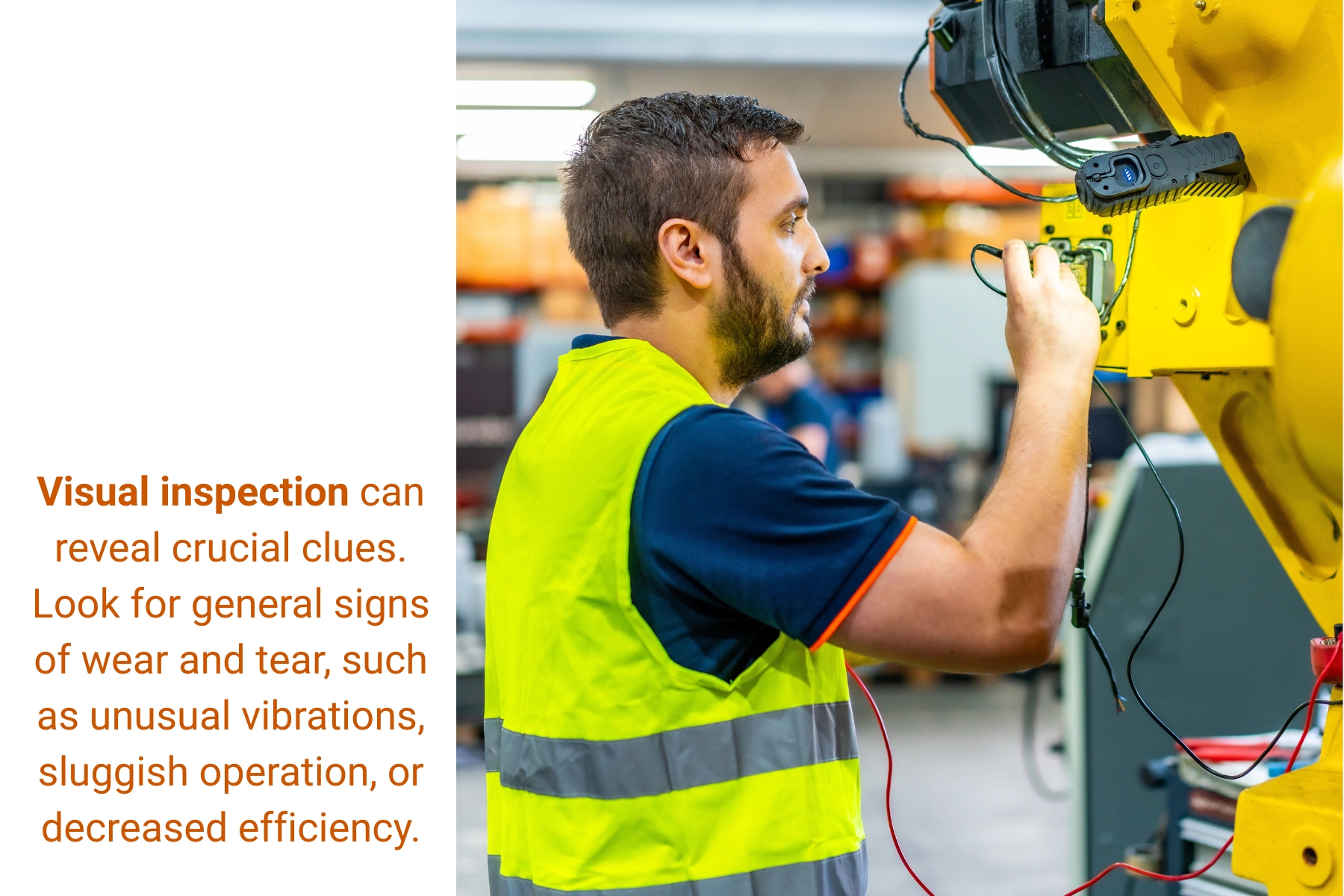

Monitoring your hydraulic system for potential problems is key to avoiding expensive downtime. Visual inspection can reveal crucial clues. Look for general signs of wear and tear, such as unusual vibrations, sluggish operation, or decreased efficiency.

Remember, early detection can save you thousands of dollars in repairs down the line. Catching these issues early is crucial.

But why do these symptoms appear?

Strange Noises: What Do Whining, Knocking, or Grinding Sounds Indicate?

Hydraulic pumps should operate smoothly—literally and acoustically. Sounds like whining or knocking are not part of its normal operation. Here’s what they might mean:

- Whining: Indicates that air is leaking into the system. This might result from loose connections or worn-out seals. It reduces the pump’s efficiency and can cause considerable damage if left unchecked.

- Knocking: Points to potential cavitation—a process where vapor bubbles in the fluid collapse, causing shockwaves. These impact the internal components, leading to wear or even breaking them entirely.

- Grinding: This ominous sound often signals metal-on-metal contact caused by inadequate lubrication or worn-out bearings.

An astute operator knows to never ignore these auditory clues. These sounds often signal underlying issues. If you hear unusual noises, investigate immediately. When caught early, repairs can be minor and manageable.

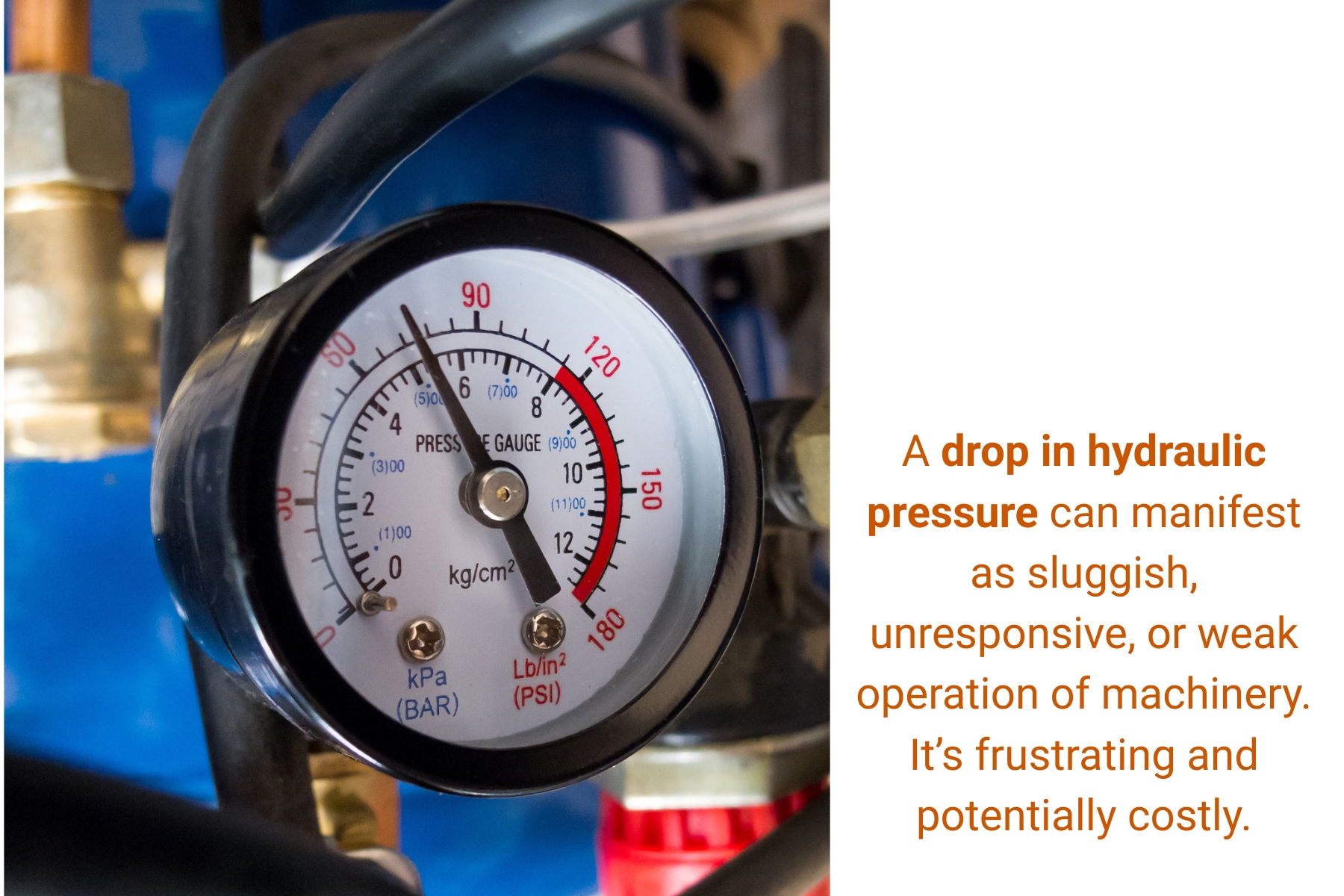

Loss of Pressure: Why Your Hydraulic System Feels Weak

A significant drop in hydraulic pressure is another red flag. This is problematic. This can manifest as sluggish, unresponsive, or weak operation of machinery. It’s frustrating and potentially costly.

The pressure, which enables the system’s force, can diminish for a variety of reasons:

- Internal Leaks: Worn-out seals and pumps result in hydraulic fluid bypassing within the system, leading to a drop in pressure.

- Valve Malfunction: Valves regulate pressure flows. If they’re malfunctioning, they might prevent the system from generating sufficient force .

- Fluid Contamination: Particles or moisture in the fluid can damage parts and reduce system pressure significantly.

Regular maintenance and inspection can mitigate these issues. Preventive checks for pressure consistency are vital for an efficient system.

Overheating: Causes and Consequences of Excessive Heat

Excessive heat is a blaring red flag in hydraulic systems. Symptoms include excessively hot pump casings and a noticeable increase in hydraulic fluid temperature. When hydraulic pumps overheat, it affects their lifespan and efficiency significantly.

Overheating happens when:

- Excessive Load: When the system is overworked beyond its intended capacity, it generates excessive heat. Maintaining operational standards helps avoid this.

- Poor Cooling Mechanism: If the system lacks adequate cooling methods, components can quickly overheat. Ensuring chillers or fans operate correctly can keep temperatures in check.

- Inadequate Lubrication: Friction without proper lubrication alternately contributes to overheating.

The consequences? Shortened lifespan of the components, increased downtime, and a hefty repair bill. Therefore, pay attention to temperature indicators.

Fix or Replace? When to Consider Aftermarket Hydraulic Pump Parts

Sometimes, even the most vigilant maintenance can’t prevent every problem. With persistent issues, the pivotal question becomes: should you fix or replace your hydraulic pump?

- Extent of Damage: Evaluate the severity. Superficial damage may only require simple fixes or replacement parts. Repairs are feasible for minor issues like worn seals or leaking fittings.

- Cost Analysis: Often, repairing might be more cost-effective than seeking new replacements. However, if repairs become frequent or if significant internal damage is present, replacement is often the most economical and effective solution.

- Availability of Quality Aftermarket Parts: High-quality aftermarket hydraulic pump parts ensure efficiency without burning a hole in your pocket. These significantly extend your hydraulic system’s lifespan, providing a cost-effective alternative to buying entirely new pumps.

But whatever your decision, think of your machinery’s long-term operation. Using reliable, high-quality parts can save on future repairs and maintenance. To learn more about using OEM or aftermarket parts, read our recent blog on choosing the right aftermarket hydraulic parts.

Conclusion: Be Proactive, Be Prepared

You are now equipped to listen and attend to your hydraulic systems with greater insight. Understanding the subtle and overt signs of pump failure makes a significant difference in the lifespan of your machinery. Regular maintenance checks, being alert to symptoms, and choosing quality aftermarket parts ensures your operations run smoothly.

Choosing the right partner for your hydraulic pump needs is crucial. Working with experienced professionals guarantees high-quality parts and reliable services. Missions Hydraulics offers expert assessment, repair, and replacement services, ensuring your systems run smoothly.

Don’t wait for a catastrophe to strike. Recognize the signs, act early, and ensure a successful and steady machinery operation.

Explore our range of high-quality hydraulic pumps and parts—all crafted to keep your operations seamless and trouble-free.

Contact us today to discuss your specific needs.